In September 2020, it was reported across tech media outlets that the Estonian company Skeleton Technologies and the Karlsruhe Institute of Technology in Germany had teamed up to “develop a SuperBattery that charges in 15 seconds.”

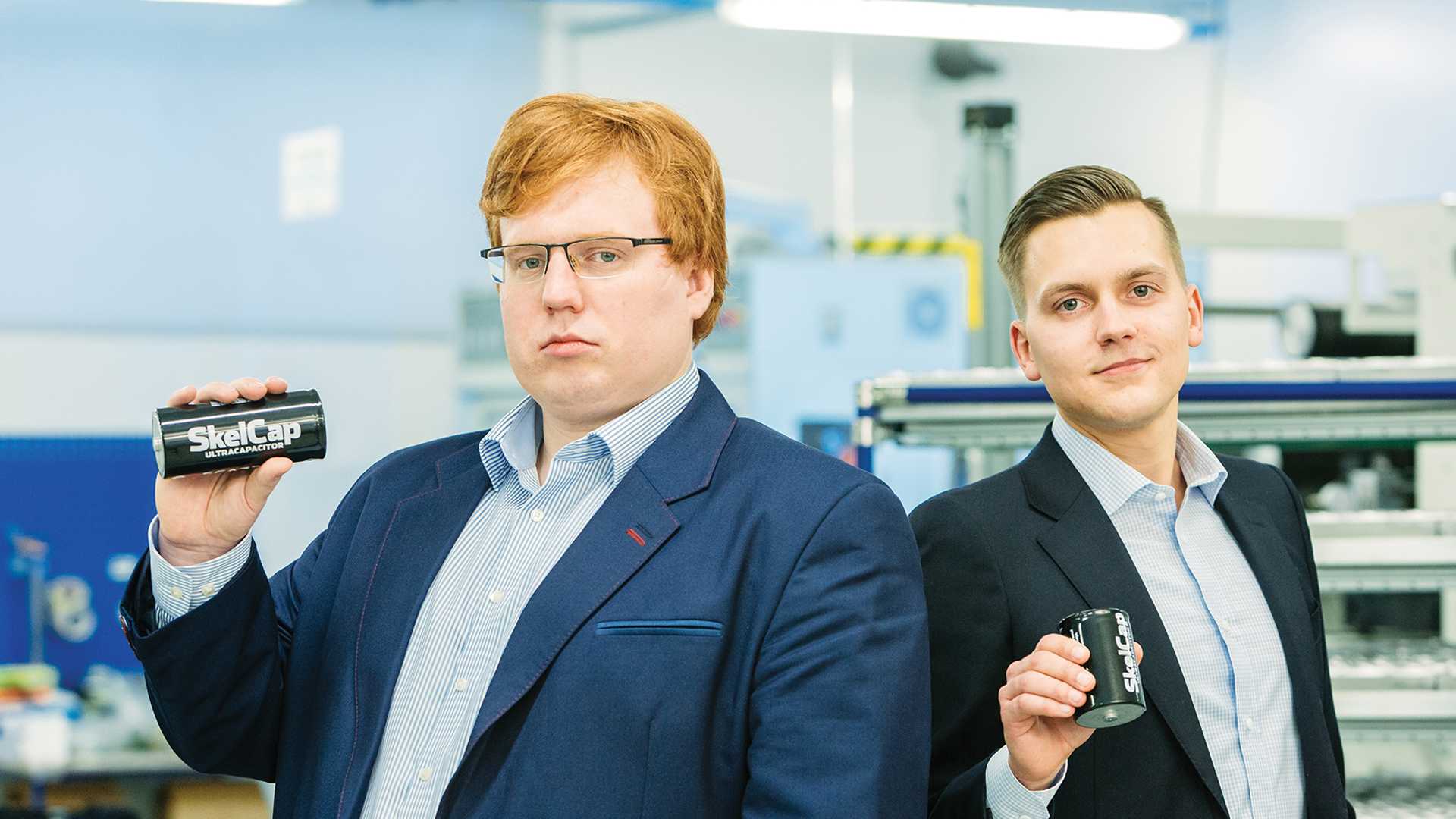

Skeleton Technologies, founded in 2009, is a producer of ultracapacitors. As Baltic News Service and ERR indicated in early November of 2020, the company was the recipient of 41.3 million Euros of equity capital, adding onto the existing investments of organizations that include EIT InnoEnergy, Harju Elekter, and Firstfloor Capital. By all accounts, this is technology that piques interest in the engineering world as much as it does for those who are primarily interested in how it can be applied. In February 2019, Tesla announced their plans to acquire Maxwell Technologies, another company that creates ultracapacitors. There are other big league competitors out there.

As a matter of clarification, though, what exactly is an ultracapacitor? And why is it so much of a trailblazer?

Essentially, it doesn't operate through chemical reactions like a typical battery does. As Skeleton Technologies has explained, ultracapacitors “store energy in an electric field.” While they otherwise function in a similar way to batteries in that they are charged up and discharged, the way they achieve this is different. For batteries, electricity's potential is held in a chemical form. A capacitor has negatively and positively charged metal plates that are spaced out, but collectively hold many electrons.

Ultracapacitors are even more tightly packed with electrical energy and have the potential to almost instantaneously charge and discharge. Imagine being able to instantly charge your smartphone after a day out and about. Not only is it a time savings, you would be more likely to use up the full extent of your device's battery before charging again. Capacitors are durable and long lasting, with one million or more charge cycles in their lifetime. They can also endure in extremes of heat and cold that would be dangerous for batteries.

The technology is not perfect, as the ability to discharge quickly can lead to an inadvertent loss of charge when not specifically instigated. Ultracapacitors sometimes hold less charge than a battery, too. But this room for improvement is being addressed by producers across the world.

The starting block of Skeleton Technologies' competitive action is the “curved graphene” technology they have patented. The lower power density of ultracapacitors is countered through “nanostructured carbon” and “a process that uses silicon carbide.”

Putting the dream of fast charging phones aside for a moment, the implications on large vehicles is big. When we think of electricity powering vehicles, we tend to think of zippy, svelte joy ride mobiles.

Yet, speaking at the opening of one of their assembly lines in Viimsi, CEO and co-founder Taavi Madiberk said “If each new truck manufactured in Europe was equipped with ultracapacitors and a regenerative braking system, more than two billion litres of fuel would be saved and air pollution would be reduced each year.”

A case study led by the company, with a delivery truck, claimed that a Kinetic Energy Recovery System, which ping pongs back and forth the accelerating and braking energy of the vehicle, “can reduce fuel consumption by up to 32%…” Conversely, a double decker bus using the company's ultracapacitors “enables a 36% fuel saving compared to a UK based Euro VI diesel bus baseline.”

The company has staff in Estonia and Germany, accounting for 50 people and 90 people respectively. Großröhrsdorf in Germany was where the company's production grew in 2017. It's said that Bitterfeld, about two hours away, is where raw material research and development happens. Both of these towns are in “Silicon Saxony.” From the manufacturing stage to product usage, American distributor Mouser Electronics has formed a partnership with Skeleton Technologies.

You can be assured that you won't be zapping yourself back to 1955 or the hoverboarding futuristic vision of 2015, but these devices have the potential to make our use of electronics more efficient and enduring.

This article was written by Vincent Teetsov as part of the Local Journalism Initiative.